|

Welcome to GoldWaveTables.com

This site has been set up to help those who need more information about wave tables, especially those involved in gold mining and minerals extraction in Australia and many other countries.

We use, sell and recommend Micron Wave Tables.

Here’s a little information about ActionMining, the USA based company behind the Micron Mill wave tables:

Here’s a little information about ActionMining, the USA based company behind the Micron Mill wave tables:

“In business since 1979 our knowledgeable and service-conscious staff are readily available to assist you in your mining equipment needs. The company maintains its original credo of “Innovators in Noble Metal Technology”, being suppliers of a vast range of products, with shipment worldwide, including the dynamic concentrator – the Micron Mill Wave Table.

We have built our storefront so that you are able to order any item from our catalog online. If there is something you can’t find, feel free to contact us and we will be happy to assist you.”

As exclusive agent in Australia, Ian can assist you in all states — Queensland, NSW, Victoria, Tasmania, South Australia, Western Australia, Northern Territory (which are listed here to assist those who are using Google or other search engines).

About the Micron Mill Wave Table:

About the Micron Mill Wave Table:

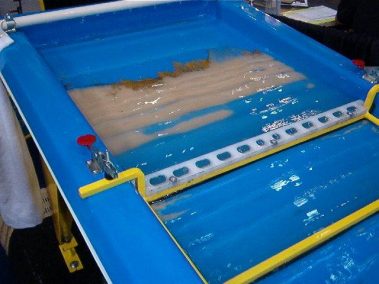

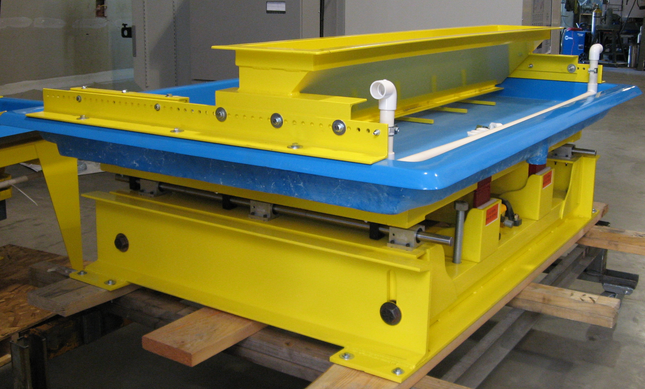

The M10 is the largest model of this impressive minerals recovery device. It does up to 8tph and the M8 model about 1tph. The compact M5 unit will soon be released for sale. For their throughputs, they have very small footprints compared to conventional shaking tables.

The M8 is the same as the M7 but is set up to operate on Australian power supply.

About Wave Tables, Ian says:

“I have personally had success with the Wave Table recovering very fine gold and other heavy minerals such as mineral sands (zircon & rutile), tantalite, scheelite, stibnite etc. Because it is so efficient at recovering very fine particle sizes, it has proved excellent as a scavenger on tailings.

Ian's mining experience:

“I have been in the mining, exploration and mineral processing industry for over 30 years. With wide mining experience including deep gold mining in the South African Witwatersrand. Also silver, lead and zinc mining in several Broken Hill mines. Also successful opal mining stints in Queensland and NSW. More recently, in both hard rock and alluvial gold mining within NSW."

About gold recovery, Ian says:

About gold recovery, Ian says:

“With gold, the Wave Table can be used in the smallest to the largest gold mine. Wave Tables can be used for full scale production purposes, or simply as a clean-up/concentration device in the gold room. The Wave Table is now increasingly being used to recover gold from test samples of a couple of kgs in size and upwards. This form of bulk testing is quite quick and the quantitative results mean that one is not just relying on fire assays, particularly in visible, free gold deposits.”

About Ian - Action Mining Australia:

Ian is the sole distributor for all the Action Mining Services product lines within Australia and can provide expert advice on minerals recovery methods. Sales have been brisk with the higher world metal prices and Ian is receiving enquiries from all over Australia as well as from Fiji, Papua New Guinea, Africa and Indonesia… and beyond.

Contact Ian:

actionmining@bigpond.com

For the best way to see gold wave tables in action,

may I suggest these links...

our slideshow,

these local videos,

and these YouTube videos.

|

Buy Gold / Sell Gold: Ian can assist you with selling your gold, and also purchasing gold. Attractive rates for domestic and international gold transactions. We can buy your native alluvial or dore gold, as well as refine your gold to 99.99% purity.

|